How did Unigreat Technology design membrane switch?

2021-02-02

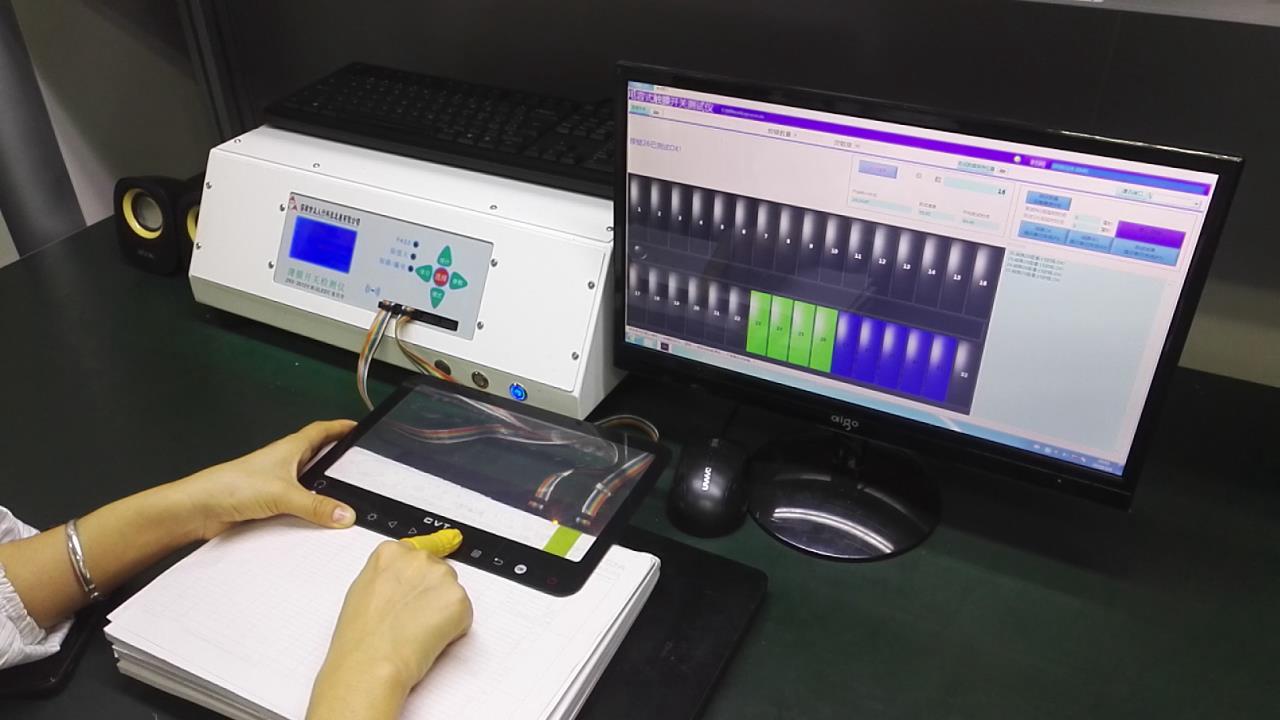

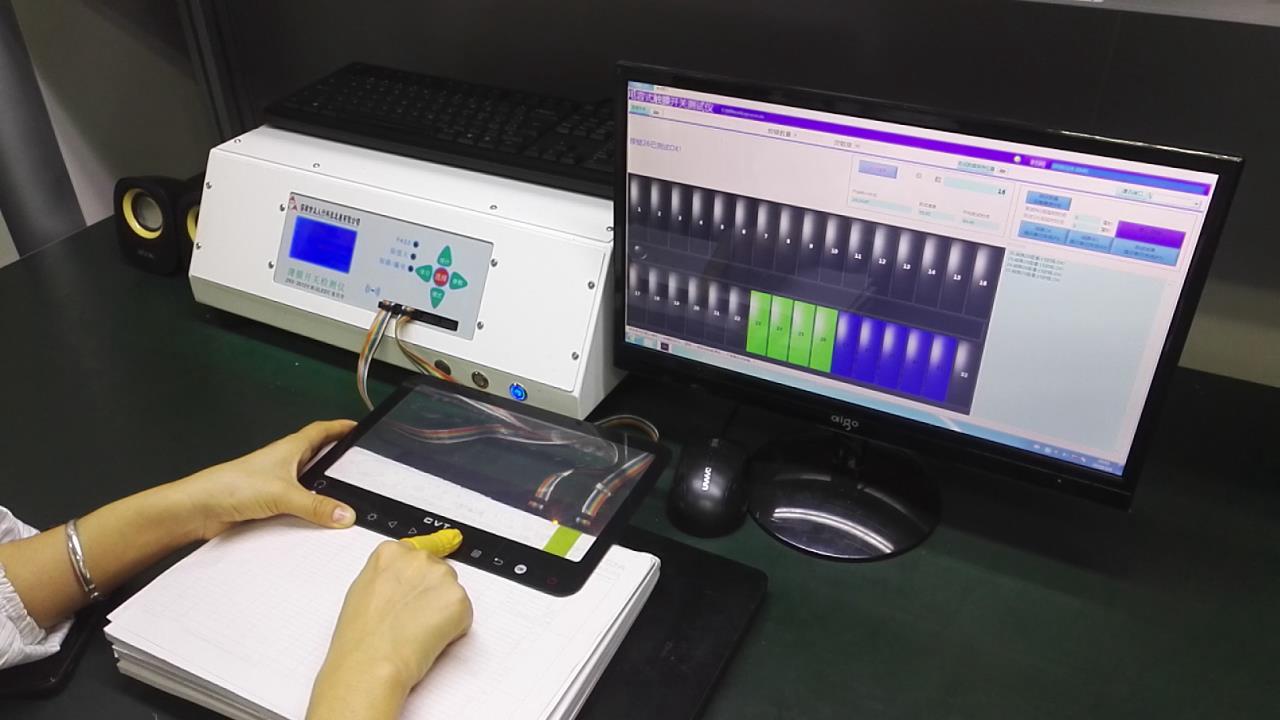

At Shenzhen Unigreat Technology Co., Ltd., the design process of membrane switch has several stages and steps, and each of them can be methodized and be done regularly. Typically, there are 4 steps for us to carry out the design procedure. Firstly, we start with gathering the necessary information and requirements from customers. This is usually achieved by either a face-to-face meeting with the client, a questionnaire (on- or off-line), or even a Skype meeting. Secondly, this step is mainly focusing on design creation. Having got in-depth research of customers and their products, target market and competitors, we will begin brainstorming to decide the colors, shapes, and other elements. The next step is evaluating the design work and doing the refinement if possible. Customers should provide any feedback they may have once seeing the design. The last step is to apply the confirmed design work into the production formally.

Unigreat Technology is seriously a BEST for manufacturing membrane keyboard from China. We offer comprehensive products at a competitive price. Unigreat Technology's capacitive sensor is various in types and styles to meet the different needs of customers. Unigreat touch switch is manufactured complying with strict shoe materials requirements. Its quality is guaranteed by the production process which is in charge of qualified QC workers. This kind of material helps protect the feet by being made into high-quality shoes that avoid possible friction and inflammation.

Unigreat Technology will set higher goals for itself in further development. Please contact us!

Unigreat Technology is seriously a BEST for manufacturing membrane keyboard from China. We offer comprehensive products at a competitive price. Unigreat Technology's capacitive sensor is various in types and styles to meet the different needs of customers. Unigreat touch switch is manufactured complying with strict shoe materials requirements. Its quality is guaranteed by the production process which is in charge of qualified QC workers. This kind of material helps protect the feet by being made into high-quality shoes that avoid possible friction and inflammation.

Unigreat Technology will set higher goals for itself in further development. Please contact us!

Custom message